| MODEL | CHUCKS | CAN (mm) |

CAN BODY HEIGHT (mm) |

THICKNESS (mm) |

MAX SPEED (cpm) |

|---|---|---|---|---|---|

| AT 541 | 8 | 52 – 105 | 38 – 210 | 0,12 – 0,25 | 800 |

| AT 541/4 | 4 | 52 – 105 | 38 – 210 | 0,12 – 0,25 | 400 |

| AT 518 | 12 | 52 – 105 | 38 – 210 | 0,12 – 0,25 | 1200 |

| AT 518/6 | 6 | 52 – 105 | 38 – 210 | 0,12 – 0,25 | 600 |

| AT 545 | 6 | 99 – 155 | 90 – 260 | 0,13 – 0,30 | 300 |

| AT 545/3 | 3 | 99 – 155 | 90 – 260 | 0,13 – 0,30 | 150 |

| MODEL | CHUCKS | CAN (mm) |

CAN BODY HEIGHT (mm) |

THICKNESS (mm) |

MAX SPEED (cpm) |

|---|---|---|---|---|---|

| AT 541 | 8 | 52 – 105 | 38 – 210 | 0,12 – 0,25 | 800 |

| AT 541/4 | 4 | 52 – 105 | 38 – 210 | 0,12 – 0,25 | 400 |

| AT 518 | 12 | 52 – 105 | 38 – 210 | 0,12 – 0,25 | 1200 |

| AT 518/6 | 6 | 52 – 105 | 38 – 210 | 0,12 – 0,25 | 600 |

| AT 545 | 6 | 99 – 155 | 90 – 260 | 0,13 – 0,30 | 300 |

| AT 545/3 | 3 | 99 – 155 | 90 – 260 | 0,13 – 0,30 | 150 |

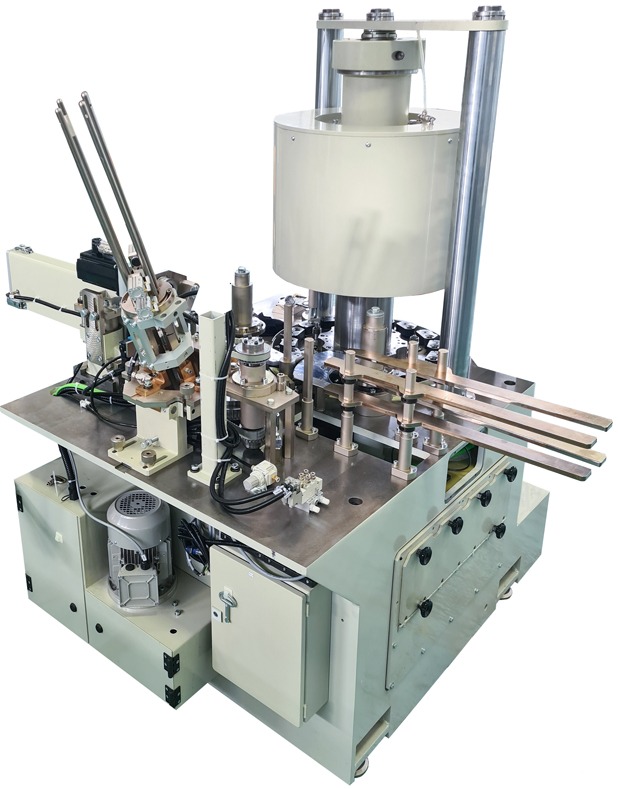

Modem interface available for on-line service, trouble- shooting and software update.

High-capacity hopper for automatic end feed.

Automatic height change.

Double oil circuit with two-way filter.

224 North McColl Road, McAllen, Texas 78501

Via Colunga, 18 – 40068 San Lazzaro di Savena (BO) ITALY